Control system

The Control System is designed for test rig control and evaluation of the measuring results after the test.

The Control System is developed together by the companies SENSUS Slovakia and ms.technology Schrempel, Austria.

Basic information

The system consists of following parts. Electronic module controlled by processor EPM, 3 electronic processor controlled modules with 16 bit AD converters for current 0-20/4-20 mA - CUC, 2 electronic processor controlled modules with 16 bit AD converters PT 500 CUT, TIME unit, program for PC. The flow is automatically adjusted with one or two pumps, adjusting valves, bypass valve and frequency controller according to the flow rate measured by electromagnetic flow-meters. Up to thirty different flow-rates can be preset in the measuring procedure.

Testing methods

- Basic method of operation is flying START-STOP method using static weighing system. There are 2 weighing systems and each is equipped with one diverter.

- Second method is flying START-STOP method using master meters (electromagnetic meters). Control system is prepared for up to four master meters. Both methods can use broken pulse method or direct comparison method when pulses are used for determination of volume of tested meter.

Testing process

All test processes are controlled by a special designed test program that is running on a PC.System is equipped with a computerized data and test management system that acquires stores and manages data of the tests performed using a computer controlled measurement system.

During the measurement all control telegrams will be sending between the PC and the PLC. The existing PLC will control following parts: open-close, pumps, FC converters, Heating units. The EPM will control or reed following parts, frequency output from electromagnetic meters, Diverters – control signal, Diverters adjustment, Diverters position change determination, Time signal – from TIME unit, Pulses from tested meter.

Measuring specifications, preparation process and ending process can be defined by user and stored as measuring procedure. The system will follow all defined steps automatically (cycle testing) or semi-automatically the operator will start the preparation procedure, and starting every measurement individually.

For each measurement, when the complete system is prepared to start the test the flow rate will be adjusted automatically including flow-diverter pressure adjustment. If the required flow rate is adjusted the test will begin.

During the measurement, all counters of EPM will count pulses from Reference Electromagnetic Flowmeter and of tested meters as well. All these information will be sent to the PC for evaluation. Most of the pressure meters are equipped with analogue output 4 to 20 mA. They are connected to the CUC units. CUC units are converting the values to digital telegram and sending them to the PC. Temperature sensors PT 500 is with 4 wire connection are connected to the CUT terminals. The CUT terminals are sending telegrams to the PC of each measure temperatures.

Program calculates all required values as average flow rate, error of tested meter, Reynolds numbers, duration of the test, pressures of the water, temperature, ambient temperature, humidity and pressure, density and other values as described by customer. After finishing the measuring cycle or last measurement the END sub-procedure can be selected to empty the test line and prepare the line to remove the tested meter.

Basic specification

- EPM unit: Processor controlled, up to 4 electromagnetic meters (2 kHz) output 1 frequency / pulse input from 0,01 to 10.000 Hz ; 2 diverters ;additional 4 inputs up to 1 kHz

- Pressure measurement (3 CUC units each 6 channels, each RS 485 Interface, up to 18 sensors with 4 to 20 mA output 16 bit converter, 4 s for measurement

- Temperature measurement (3 CUT units each 8 channels, each RS 485 Interface, up to 16 sensors PT 500, 16 bit converter, 4 s for measurement, Temperature range 0 to 100 °C

- Valves - Open close: Controlled from PC program via PLC

- Positions detected Open, Close, Opening, Closing

- Flow meters: up to 4 electromagnetic flow meters

- Diverters: Two diverters each with pressure adjustment and with 5 sensors for detection of position

- Flow adjustment devices: 2 adjusting valves – remote controlled; 2 pumps, 1 with frequency, speed controller converter, bypass

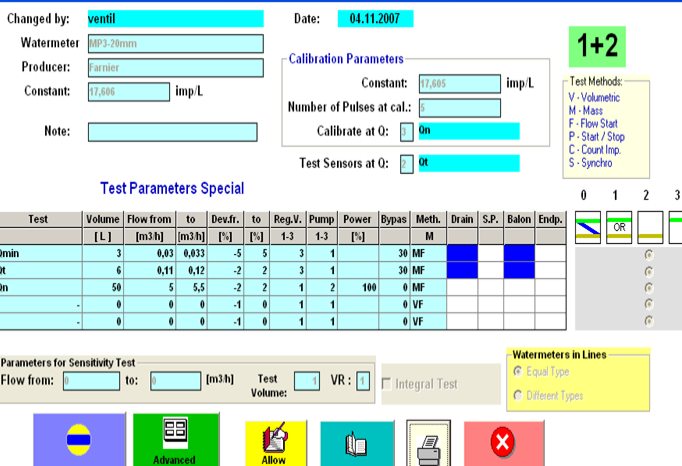

Measuring software

- Language option: All displayed information in English / German / Italian. The program calculates the measuring results of the test pieces for all test methods

- Number of measuring procedures: 500

- Maximum quantity of measurements in one measuring procedure 30

- Definition of each measurements in the measuring procedure: (Method of testing,Testing flow rate range, Duration of the measurement / measuring volume,Maximum permissible error limits; Definition of adjusting line/ weighing system

- Every measurement can be repeated 99 times

- The complete cycle can be repeated 99 times

- Process visualization screen

- The test cycle is flexible for different flow meter types (flow rates, evacuation time, drainage time, etc.)

- Test report format : ISO 4064/OIML R-49 standards

- Other format: Generation of protocol table in EXCEL FORMAT

- Special test report: Defined by user